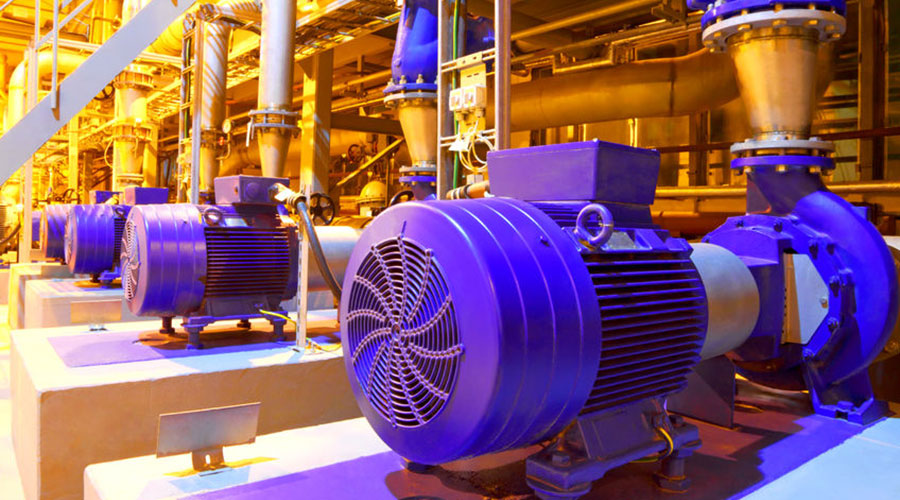

Electric motor driven sub-systems

Best Available Technique (BAT)

BAT is to optimise electric motors in the following order:

- optimise the entire system the motor(s) is part of (e.g. cooling system)

- then optimise the motor(s) in the system according to the newly-determined load requirements

- when the energy-using systems have been optimised, then optimise the remaining (non-optimised) motors according to criteria such as:

- prioritising the remaining motors running more than 2000 hrs per year for replacement with EEMs

- electric motors driving a variable load operating at less than 50 % of capacity more replacement with EEMs than 20 % of their operating time, and operating for more than 2000 hours a year should be considered for equipping with variable speed drives.

Brief technical description

Electric motors are widely used in industry. Replacement by electrically efficient motors (EEMs) and variable speed drives (VSDs) is one of the easiest measures when considering energy efficiency. However, this should be done in the context of considering the whole system the motor sits in, otherwise there are risks of:

- losing the potential benefits of optimising the use and size of the systems, and subsequently optimising the motor drive requirements

- losing energy if a VSD is applied in the wrong context.

Achieved environmental benefits

Improvement of energy efficiency

Applicability

The key systems using electric motors are:

- compressed air

- pumping

- heating, ventilation and air conditioning

- cooling

EE Metal

EE Metal