Presentation of the company

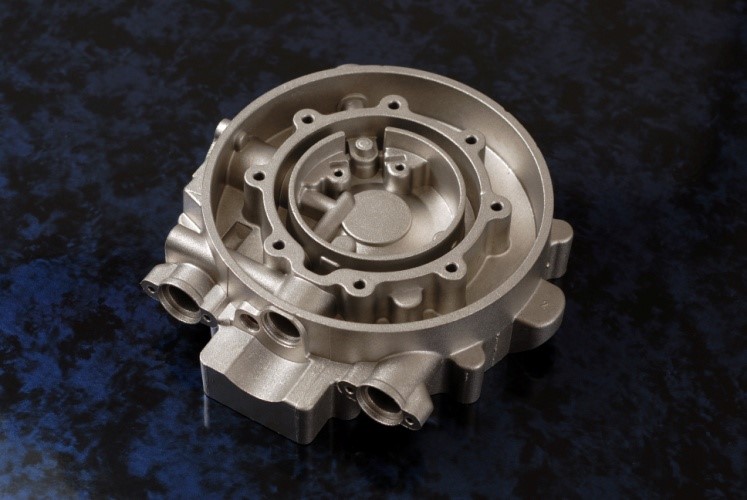

Die casting aluminum and zinc alloy components is the core business of La Cibek. This small company with about 20 employees manufactures products for several market sectors, such as hydraulic, electrical, oil & gas, agriculture, pneumatics, industrial automation and cleaning machines, professional appliances, measuring instruments and LPG equipment for automobiles. Flexibility and innovation are key factors for the success of this company, from in-house designing service for taylor made solutions to production process itself.

Context and challenges

La Cibek has been always interested in energy efficiency in order to optimize its consumption, improve the productivity and reduce the environmental impact.

For this reason the company joined enthusiastically the EE-Metal project and decided to pursue a continuous improvement plan through implementation of ISO 50001 energy management system.

Actions

Over the last years, La Cibek achieved interesting results of energy efficiency thanks to some improving actions that have been realized by company management:

replacement of old lamps with LED technology in foundry department, installation of high efficiency furnace in substitution of an existing die casting equipment, variable speed drive engine on air extraction plant, monitoring system with energy meters for electricity and flow meters for natural gas of furnaces.

According to energy audit results, company is actually evaluating actions for optimization of air compressed production plant and cooling system of presses.

EE Metal

EE Metal